Large manufacturing companies will use plastic injectio […]

Large manufacturing companies will use plastic injection moulding to create small plastic parts on a regular basis. If the company creates a huge amount of products on a monthly basis then this process will be ideal. It is known as being the best way to create small objects in bulk and it's not hard to see why.

Most of the time, a large manufacturing company, such as a car maker, will need to create thousands of plastic parts for their cars. Usually the only way to do this in a timely manner is to use a plastic injection moulding machine.

These machines are easy to use and for the most part do all the work. They require simple supervision and perhaps an on site mechanic or technician but apart from that they work on their own. A lot of people are unaware of the process but it's pretty straight forward.

Firstly, the machine will be loaded with plastic which will then be passed into a melting chamber. Once the substance is melted it'll then be pressurised into a small moulding compartment. This mould will then be cooled (usually with water) and once it is cool enough it'll be released and that's it.

There may be a few extra steps involved such as a mixing compartment which will allow the manufacturer to mix in any other substances such as colour or perhaps a pattern of some sort. This process is a little more complicated and will depend entirely upon the companies needs.

The most basic plastic injection moulding machines are quite expensive but they don't require too much in the way of up keep. Usually simple supervision is all that's required and this is probably why they're so popular. They are very cost effective and can really help speed up a production line.

Another thing that makes them so popular is that they are exceptionally accurate and can create thousands of plastic parts in a matter of hours. Obviously, time frames will depend on the quality and detail of the parts being made but usually it's a very fast process.

So, if you're interested in buying a plastic injection moulding machine, you're probably wondering where to start. Well, like with all major purchases your first step should be research. Make sure you're aware of the different models available and ensure you know what you need.

You'll also need to figure out if you really need to buy a machine. Sometimes a project is small enough to rent a machine from another manufacturer. This can be cheaper but it really depends on how much work you need done.

Once you have all the facts you should then be able to approach companies and businesses that deal with these services or sales. As long as you keep your facts straight you should be able to come to some sort of arrangement that's agreeable for both parties.

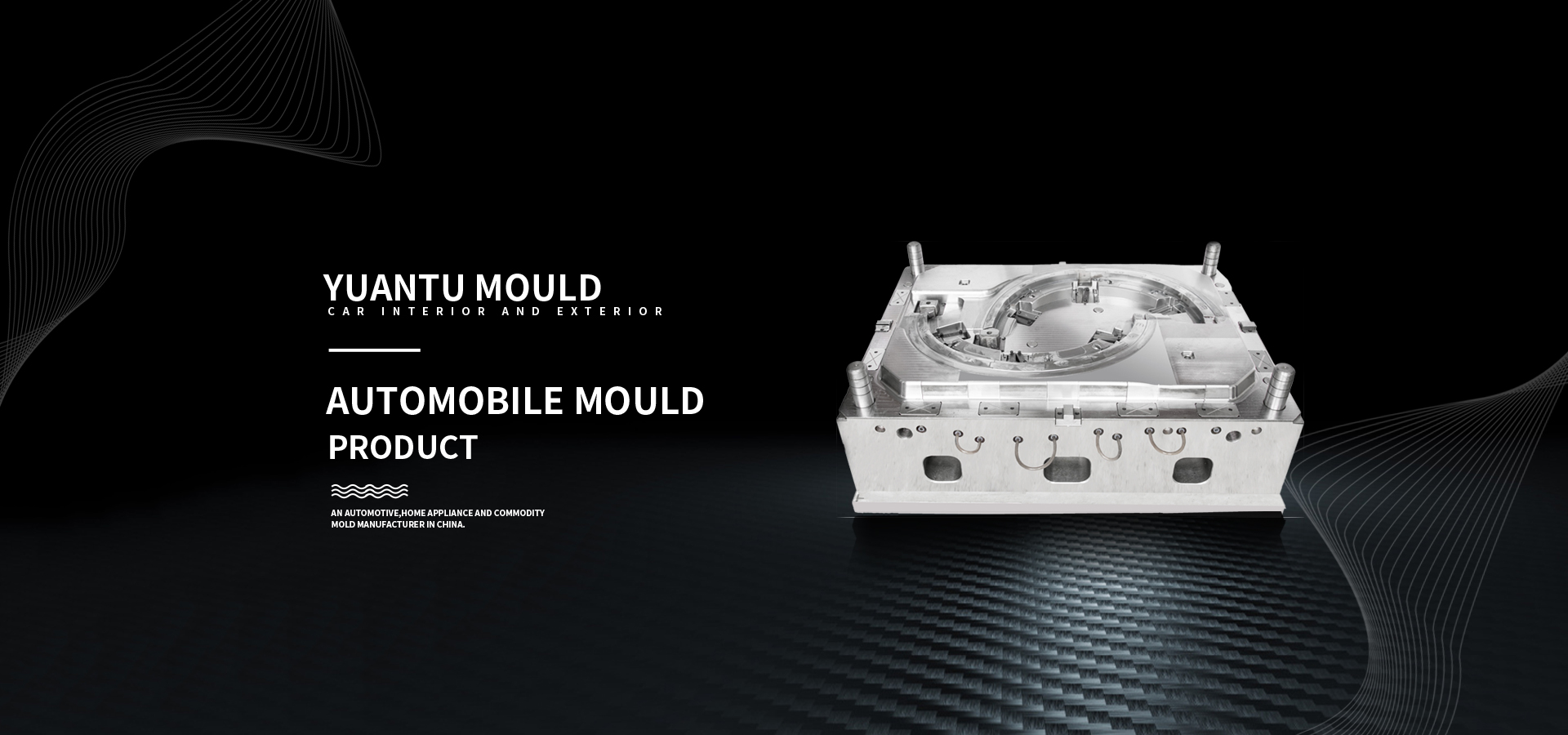

Taizhou Huangyan Yuantu Mould Co., Ltd. is Plastic Injection Mould Manufacturers: https://www.yuantumould.com/